With the engineering skills crisis worsening year on year, Morson Group has once again shown a proactive approach to tackling the problem by inspiring a new generation of engineers to become leaders in their field with their annual Early Careers Development Programme...

READ MORE…

Morson Group reports strong financial performance for year end 2023

Morson Group has recorded another record year as Group revenue jumped from£1,151.7m in 2022 to £1,332.9m in 2023, underscoring Morson’s ability to scaleits operations efficiently while maintaining high levels of service and client satisfaction. The Group also reported...

The Morson STEM Foundation Impact Report 2024

Our purpose is to positively impact lives every day, and every member of the Morson Group is driven to fuel innovation, empower industry and enable opportunities for people. The UK's ongoing STEM skills shortage has been estimated to cost the UK economy £1.5billion...

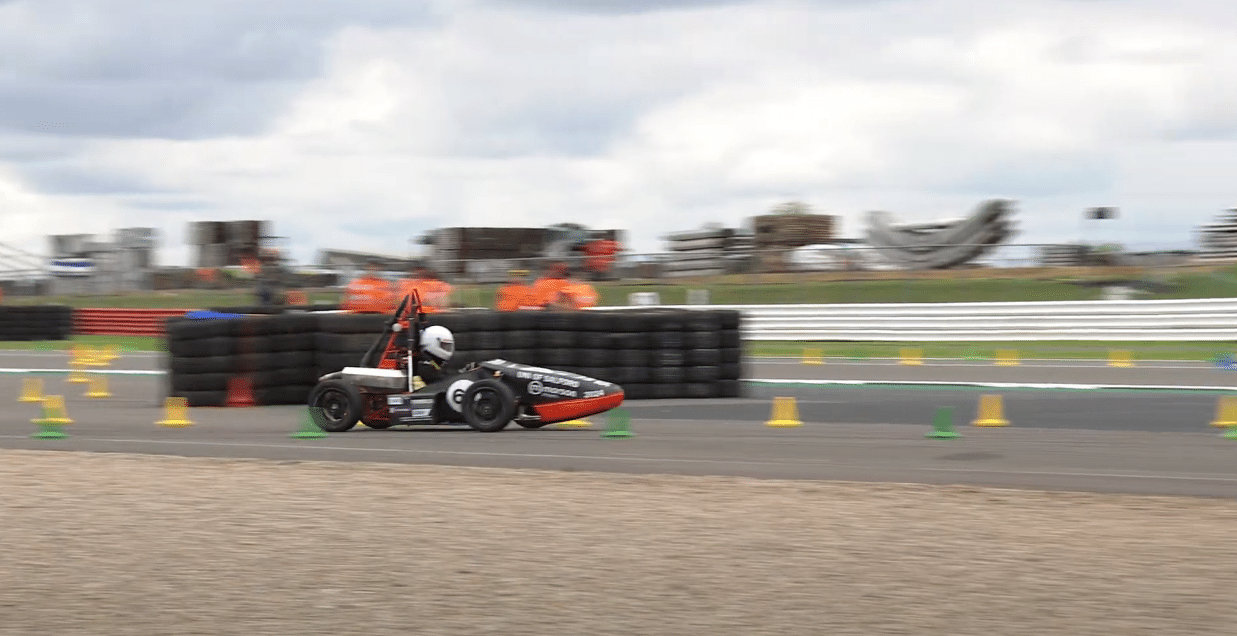

Students from the University of Salford’s Salford Racing team celebrated an amazing achievement at the annual Formula Student event, ranking P8 in the world in the prestigious student engineering competition.

Taking place each year at the home of British racing, Silverstone, the IMechE Formula Student event is a student engineering challenge aimed at developing the next generation of world-class engineers. Students design and build a race car from scratch, and then put their engineering and business skills through a series of challenges, including chassis, noise, brake tests and more.

Morson sponsors the team as part of our STEM Foundation programme, which aims to increase the talent pipeline for STEM by widening participation and creating pathways into education and training.

In 2024, the Salford Racing team not only passed all scrutineering challenges for the first time ever, they also managed to make the endurance race, a 22km test of the cars’ reliability and overall pace. The final stage was completed by the two drivers, earning the team an amazing 8th place finish overall, soundingly beating all of the other North West-based universities, including the University of Central Lancashire, the University of Manchester and the University of Bolton.

This is by far the best result the team has ever achieved (P46 in 2023, P31 in 2022, P58 in 2019). During the 2023 event the team were unable to get past the noise test, as a problem with the engine upon arrival at the track had led to a frantic rebuild, which sadly led to time running out. But there would be no such issues this year, as the team completed the build 48 hours ahead of their 2023 time.

Ollie Parsons, an aeronautical engineering graduate who took on the role of Team Principal for the end of the 2021 season through 2022, talks about the important skills required to make the project work:

Rigorous build and testing

TThe car consists of a single cylinder engine and a space-frame chassis made up of steel tubes. The students buy long 6m lengths of tube steel, which they laser cut, and weld together into the design that they have come up with. Once assembled at the event, the car faces a series of scrutineering challenges to judge the car overall. Design judging asks students to explain the design engineering decisions behind the car they have built. Cost and manufacturing assesses their understanding of the real-world implications of building a design, including how much will it cost to make components at scale, and how the manufacturing processes affect that.

In the business presentation the team pitch a fictitious business plan to a series of judges in a Dragon’s Den style format, asking for investment in the continued growth of their company.

Before the engine can be started and the car moved under its own power the team must prove to motorsport safety experts and IMechE scrutineering volunteers that it is safe. Technical scrutineering (“Tech”) involves passing a rigorous checklist, ensuring that the car complies with both the 190-page Formula Student rule book and adheres to general good engineering design practices. Safety involves includes checking the drivers can escape from the car within 5 seconds, starting from a fully strapped in position and ending with both feet on the ground and not touching the car, and ensuring that protective safety equipment is in date and undamaged.

Chassis checks the structure of the car matches the detailed chassis design that was submitted for review by design judges. This is important to check that the car will be strong enough to keep the driver safe in the event of a crash.

Tilt tips the car over at 45 degrees and then 60 degrees to check the centre of gravity is low enough for safe operation, and that the car won’t be leaking fluids like oil, coolant, or petrol all over the track. Noise checks the car is underneath the maximum noise level at a particular engine speed/RPM. The RPM is calculated to achieve a certain linear piston speed. Brake checks the car’s brakes can stop the car quickly and effectively.

Upon completing the scrutineering challenges, the car is then put through it’s paces on a custom track on Copse corner on the Silverstone track on Sunday. The endurance race is designed to test the cars reliability and overall pace, with 25 laps of the circuit needing to be completed in order to attain a final ranking in the competition.

As they’d never before passed all the required stages of scrutineering, the Salford Racing team had never been on the track before. The two drivers completed the endurance race in good time, and finished the event ranked in the top 10 globally.

Dr Maria Stukoff, Director of the Morson Maker Space at the University of Salford, commented:

“I’m just proud as punch of the team for making the track for the first time ever. Last year’s team had real battles on their hands, having to work through the night to even get through to scrutineering but ran out of time. But the 2023 team, some of whom form part of the 2024 cohort, was able to pass on their experience nad learning onto this years team, which really showcases how successful it is when students have that longevity to pass on what they learn to the next generation.

I see students come into first year and join Saldord Racing and go all the way through to graduate, there’s so much personal learning that goes on. Not only have they learned teamwork and negotiation skills, but the tenacity and that sense of resilience for when things don’t go right. They grow with all of those ‘smart skills’.”

Click here to find out more about how we’re collaborating with businesses to understand their skills needs and aligning them with a strategy for creating career opportunities developing skills, delivering social value, and enabling brighter futures.